Cryogenic Deflashing

Cryogenic Deflashing is a process used on plastic and rubber parts to remove molding flash and/or machining or grinding burrs.

What is Cryogenic Deflashing?

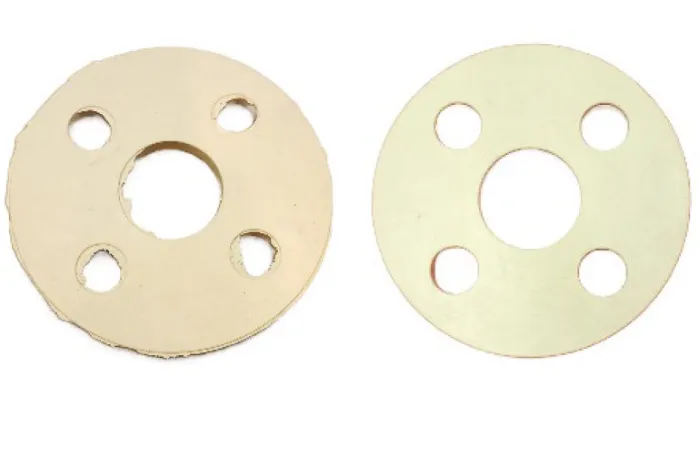

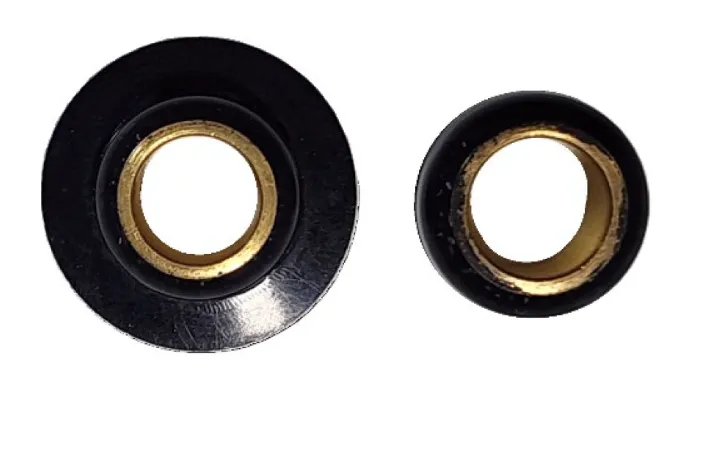

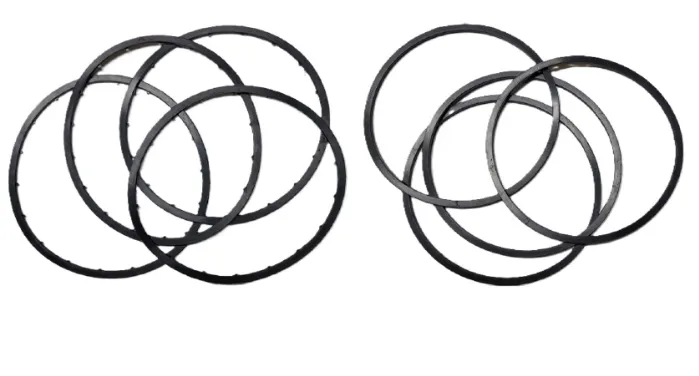

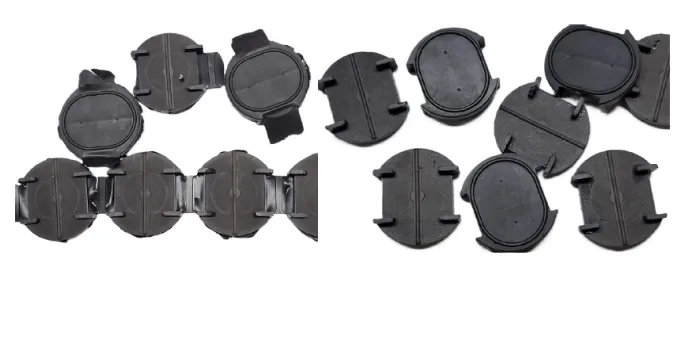

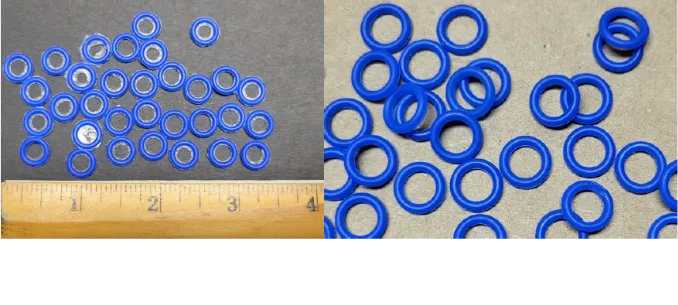

Before and After Comparison

Cryogenic deflashing is an advanced process that uses extremely low temperatures—achieved with liquid nitrogen—to make excess material, such as flash or burrs, brittle. These imperfections are then removed cleanly and efficiently by blasting the parts with a high-velocity cryogenic-grade media, such as plastic or other non-abrasive particles. This method avoids damage to the part itself, ensuring the final product is both clean and functional.

What can it do for you?

Our Leonard Enterprises CMB-2 Cryogenic Deflashing Machine stands out as an industry leader, delivering exceptional results processing plastics and rubbers. With the ability to efficiently handle up to 2 cubic feet of parts per batch, the CMB-2 is both powerful and scalable. Paired with a 4,000-gallon bulk liquid nitrogen tank, it ensures that large-scale operations can run seamlessly, minimizing the risk of downtime due to material shortages.

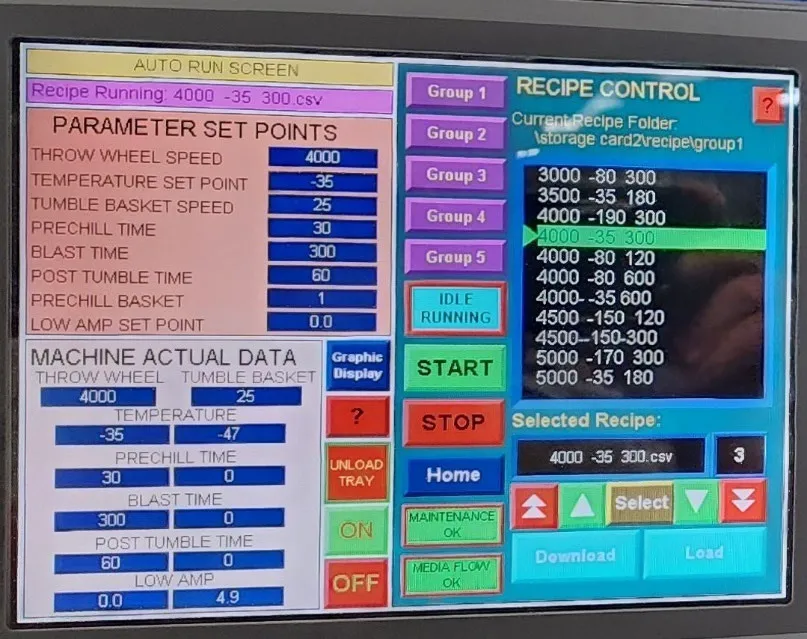

Customization for Precision

- Media blast velocity – Fine-tuning this ensures just the right amount of force is applied to remove flash without damaging delicate parts.

- Media size – Choose the size of the media particles based on the material type and complexity of the part.

- Basket speed – Adjust rotation speed for fragile or intricate parts to ensure uniform exposure to blasting media.

- Cycle time – Optimize the process for speed and thoroughness depending on batch size.

- Temperature – Maintain exact cryogenic conditions tailored to each material’s specific properties.

These customizable options make the CMB-2 versatile enough to handle parts of varying sizes, shapes, fragility, and material composition. Whether it’s a small, flexible rubber gasket or a rigid, high-performance plastic housing, our cryogenic deflashing is up to the task.

How it’s done

Parts are placed bulk in the machine basket.

The basket of parts is sealed in an enclosed chamber.

With gaseous nitrogen the chamber of parts is lowered to cryogenic temperatures as low as -200°F.

The basket of parts is then rotated while being blasted with fine polycarbonate media breaking off the flash or burr on the part.

Parts are removed from basket.

Ideal Applications Across Industries

We have discovered that cryogenic deflashing has become a game-changer in numerous sectors, where consistency, quality, and speed are critical. Below are just a few examples of industries where it shines:

Automotive: Manufacturers produce millions of precision parts such as O-rings, seals, and gaskets. For these applications, eliminating flash or burrs without altering the integrity of the part is essential. We can handle these tasks efficiently, enabling faster assembly and better product performance.

Medical Devices: Components like surgical tubing, diagnostic equipment housings, and seals demand flawless surfaces due to strict compliance standards. Cryogenic deflashing gently removes imperfections without introducing contaminants, making it an ideal solution for these sensitive applications.

Electronics: For parts like connectors, encapsulations, and switches, flawless production is key to reliable functionality. The precise control ensures that even intricate components emerge defect-free.

Consumer Goods: Products such as grips, handles, or overmolded assemblies benefit from the enhanced aesthetic and functional accuracy provided by this deflashing technology.

Aerospace: Lightweight, durable plastics and rubbers are often used in specialized parts for aircraft. Our cryogenic deflashing process ensures these parts are flash-free without compromising their strict dimensional tolerances.

What are the benefits?

Removing flash and burrs manually is inexpensive but also slow and inconsistent.

Removing flash and burrs through the cryogenic deflashing/deburring process is:

Cost-effective

Consistent

Since every aspect of the process can be customized to suit specific needs, our cryogenic deflashing process delivers uniform results time after time. This means fewer defective products, greater consistency, and improved quality assurance.

Computer-controlled, customized programs (or recipes) can be written for each part making the process repeatable on future lots and consistent over the part life.

Quick

With the capacity to process 2 cubic feet of parts per batch in a single cycle, we can drastically reduce processing time. High-volume manufacturers save significant labor hours and increase throughput without sacrificing quality.

Typical turn-around time is 1-3 days.

Does Not Damage Parts

Manual deflashing methods often risk damaging delicate structures. Cryogenic deflashing’s gentle, non-abrasive approach ensures that even fragile parts maintain their structural integrity.

Our process removes only the flash or burrs being targeted, maintaining edges and geometries that are critical to part function.

Range of Materials

While cryogenic deflashing handles plastics and rubbers exceptionally well, it’s important to note that cryogenic deflashing is not suitable for metal parts, as metals do not respond to cryogenic temperatures in the same way as polymers do. Most natural and synthetic rubber and plastic polymers can be deflashed/deburred. (NR, NBR, EPDM, FKM and many more.)

Environmentally Friendly

Cryogenic deflashing does not rely on harmful chemicals or abrasive media that could create hazardous waste. It’s a cleaner, more sustainable solution for modern production lines.

Before and After picture examples of large parts, small intricate parts, incoming sheets of parts.

Sample runs available for evaluation

If you’re in an industry that demands meticulous attention to detail and high-volume production efficiency, it’s time to consider working with Valmac Industries. With our robust capabilities and product finishing expertise, we can offer an innovative solution to keep your production line running smoothly—and your products coming out perfectly.