Flat Lapping, Grinding and Polishing Services

Valmac Industries, Inc. has many capabilities to process flat surfaces on customer parts to the desired thickness, flatness, parallel and surface roughness. This broad range of capabilities gives us the ability to process a large variety of part sizes and materials from small lots to production quantities. Please feel free to contact us to discuss your flat lapping, grinding or polishing needs.

Flat Lapping

Flat lapping is a process where a part is rubbed on a flat plate with loose abrasive resulting in the part being “lapped” flat to mirror the plate flatness. While this can be accomplished one part at a time by hand, with a lapping machine multiple parts at once can be flat lapped with much more efficiency while maintaining tight tolerances. Valmac Industries utilizes single sided lapping machines to offer flat lapping services to our customers.

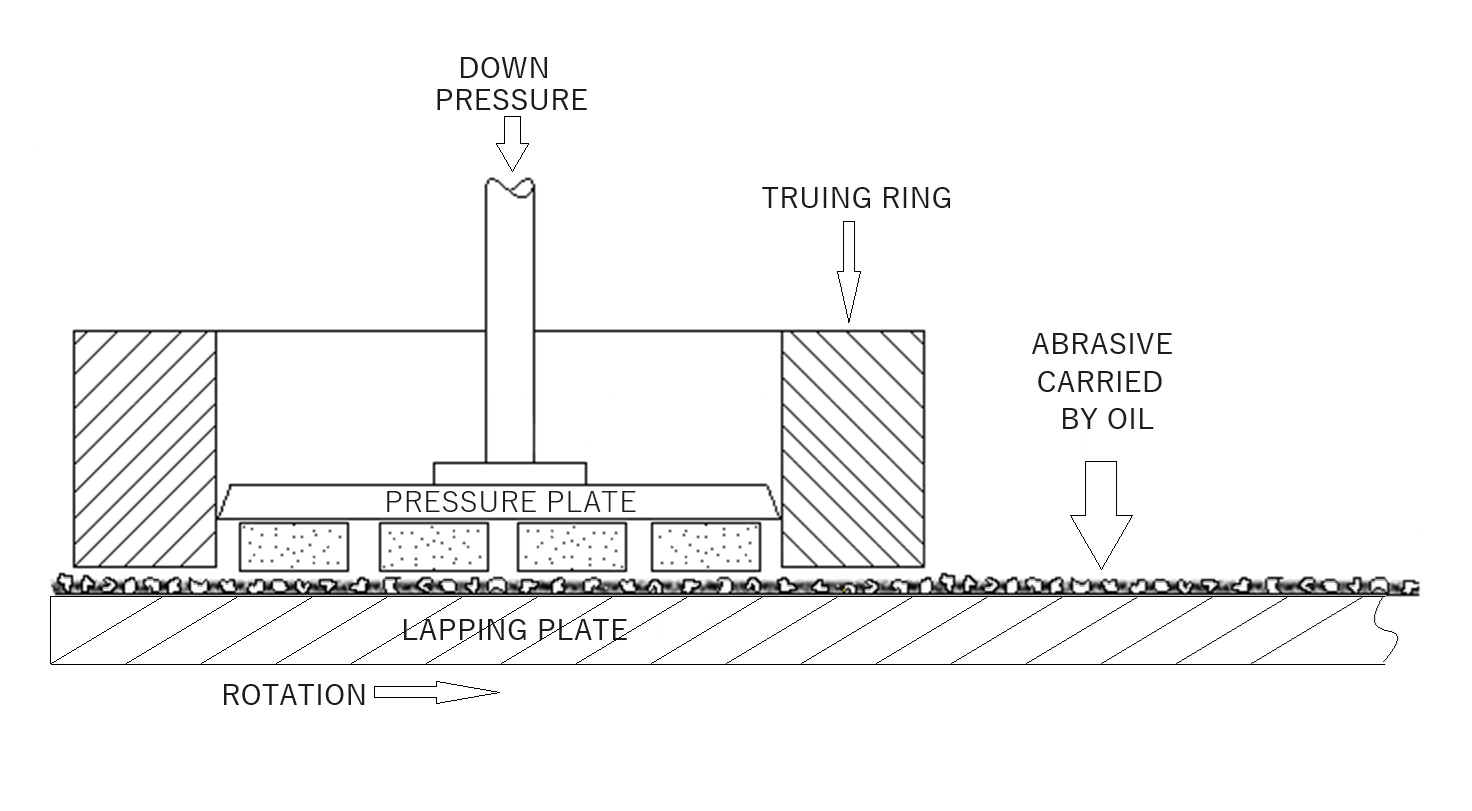

In flat lapping, parts are placed inside a truing ring. The ring of parts is placed on the lapping plate and a pressure plate is lowered onto the parts in the ring. The lapping plate is then rotated while abrasive and a liquid vehicle is dispensed on the plate developing a film of abrasive slurry between the parts and the plate thereby flat lapping the part to a mirror shape of the plate while the truing ring maintains lapping plate flatness. The part surface appearance produced range from a dull mate with very fine micro scratches to more reflective finishes when finer abrasives are used.

Flat lapping has many advantages over other flat surface machining processes.

- Superior part flatness measured in helium light bands of .000011”.

- Flat lapping can consistently produce surface flatness shapes of slightly concave or convex only.

- Ideal for part sealing surfaces with stringent flatness and surface roughness requirements.

- Final thickness and parallel tolerances to .0002” can be achieved.

- The slow and gentle stock removal generates little heat and stress to the part.

- Delicate parts and parts as thin as .010” can be processed.

- Most any part material can be flat lapped including difficult to grind Super Alloys.

- In most cases little to no tooling or setup is involved.

- Parts that are difficult to magnetically chuck and grind can easily be flat lapped.

- Frequently used as a final processing step after rough grinding or machining.

Quality Flat Lapping

Valmac Industries has over 38 years of Flat lapping experience. With this experience and know-how, we can tailor the flat lapping process variables of abrasive, pressure, lapping plate composition and speed, to flat lap a variety of parts and achieve the required part tolerances. We can also process a variety of part sizes with any one of our 16 lapping machines, ranging in size from a Benchtop model with a 12” lapping plate to our largest machine with a 72” lapping plate and 27.5” diameter lapping rings.

What is... Double-Disk Grinding

Double Disc Grinding

Double Disc Grinding is a precision grinding process which grinds two opposing faces of a part simultaneously to achieve the required part thickness, parallelism, flatness and surface finish. In Double Disc Grinding, the ground part is not chucked or held rigid while being simultaneous ground on both sides, it remains in a free state. By grinding in this free state, with little stress on the part, the flatness and parallelism requirements can be more efficiently achieved versus other flat surface grinding methods. This also means the ground part materials does not have to be magnetic so most any metals, plastics and other part materials can be ground with the proper grinding wheels.

Valmac Industries can utilize any one of our nine Through-Feed or Rotary Through-Feed Double Disc Grinders to combine a continuous part feed with high stock removal per pass to yield a low cost per part with production volumes. With Double Disc Grinder sizes from 12” to 30” in grinding wheel diameter Valmac Industries can Double Disc Grind parts of many shapes from ¼” to 10” in size and .035” to 4” thick.

Valmac’s Stahli DLM 1000mm Fine Grinder

Fine Grinding

Fine Grinding is a flat grinding process capable of producing part thickness, flatness and parallelism better than or near the precision of flat lapping but with the speed of grinding. Fine Grinding can be utilized to grind two opposing sides of a part simultaneously or single sided applications where only one side of part is ground.

Double Sided Fine Grinding with Top and Bottom Diamond Grinding Wheels

Single Sided Fine Grinding with Top Diamond Grinding Wheel and Bottom Dummy Wheel

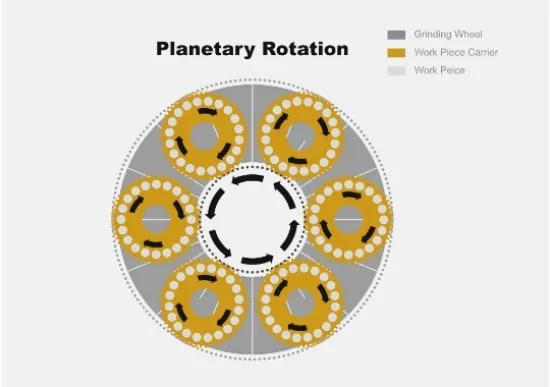

Fine Grinding utilizes diamond or cubic boron nitride (CBN) grinding wheels with a robust machine design built for using these superabrasives. The process variables of grinding wheel and parts carrier speeds and directions along with down force pressure is programmed in process steps specific for each part. This combined with a dynamic planetary rotation of the parts during grinding and a built-in precision sizing probe give the process repeatable results load after load.

Our Stahli DLM1000mm Fine Grinder is capable of processing a range of part sizes from 3/8” to 13” and thicknesses from .032” to 4”. With the proper diamond or CBN, most materials can be processed. Valmac’s current stock of diamond grinding wheels excels in grinding ceramics, plastics, carbides, hardened steels and many powdered metal parts.

Flat Surface Polishing

Valmac provides Flat Surface Polishing services on parts that require an improved surface finish beyond what flat lapping can accomplish. Using fine abrasives with polishing fabrics attached to a flat lapping plate, a parts’ lapped surface can quickly be polished to improve its surface roughness without degrading its flat lapped flatness.

Initially parts can be polished to achieve a reflective finish for measuring part flatness with an optical flat or when a lower surface roughness is required. This can be necessary with parts that have stringent requirements for a flat sealing surface. Further flat surface polishing can achieve a scratch-free, mirror-like surface.

Many materials can be polished including brass, soft and hardened steels, alloys, carbides, ceramics and others.

Surface and Blanchard Grinding

For small quantity lots of parts that require flat surface grinding Valmac performs traditional Surface and Blanchard Grinding. Our Blanchard Grinder can grind flat surfaces of magnetic parts that fit within its 36” diameter chuck and is capable of quickly removing large amounts of stock. Our ELB Automatic Surface Grinder with a 9” x 16” chuck can grind small lots of parts to precision tolerances with excellent surface finishes.

Timesavers Belt Sanding

Valmac Industries, Inc. uses a Timesavers 9” wide wet belt sander to create directional mill finishes or to remove fine imperfections of flat surfaces of metal parts. Coarse or very fine grades of surface roughness can be achieved with the correct abrasive grit of sanding belt. With this wet process, most metals can be processed including copper, aluminum, soft and hardened steels, stainless steel and other alloys.